you have just

Found

the best

resource centre

there is,for

Wound

cores

there is,for

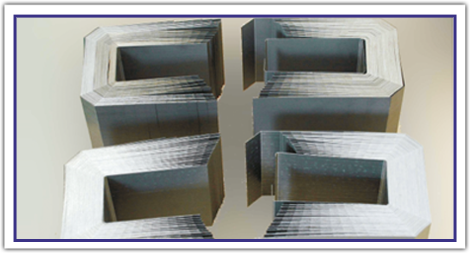

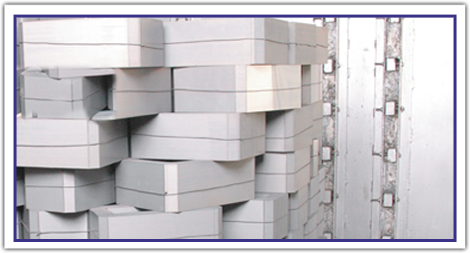

- Wound Core

- Round / Donut Shape Core

- Rectangular Core

- Step Core

- Gap Wound Core

(From 1 Kva to 1500 Kva or upto 315mm width)

- DUO Core

- Distributed Gap Core

- Diverging Distributed Gap Core

- E Core

Cores are wound after slitting is done as per the required shape, on the core-winding machines. The winding machine automatically stops when the pre-decided dimension is reached.

After winding, the cores are stress-relief annealed to restore the magnetic properties. The core are bonded where necessary, to provide increased firmness. All cores are spray painted if required, and tested for magnetic properties.

- WOUND CORES QUALITY CHECK

On receipt of material from slitting department, we enter the necessary data of the material in respective job record. Once the core gets ready, quality personnel checks and enters the record of its dimensional and its magnetic properties in the job record and send it for colour coating if require or direct packing.

- STANDARD DIMENSIONAL TOLERANCE – WOUND CORES

| Inside Diameter (d) | Outside Diameter (d) |

Height (h) |

||||||

OVER |

UPTO |

TOL. |

OVER |

UPTO |

TOL. |

OVER |

UPTO |

TOL. |

30 |

100 |

+1.2 |

030 |

100 |

+1.5 |

0 |

150 |

+ 1.0-0 |

100 |

150 |

+1.5 |

100 |

200 |

+2.0 |

150 |

200 |

+1.2-0 |

150 |

200 |

+2.0 |

200 |

400 |

+3.0 |

200 |

500 |

+2.0-0 |

200 |

400 |

+3.0 |

400 |

800 |

+4.0 |

500 |

- |

+3.0-0 |

400 |

700 |

+4.0 |

- |

- |

- |

- |

- |

- |

- GUARANTED ELECTRICALS PROPERTIES FOR WOUND CORES

Sr. No. |

Grade |

Maximum Guaranteed No Load Current at 1.5T and 50 Hz |

1 |

M4 |

0.32 AT/CM |

2 |

M5 |

0.36 AT/CM |

3 |

M6 |

0.42 AT/CM |